Floating is the future of offshore wind

Floating turbines can be located in areas with sea depths over 60 metres, harnessing the best wind resources and opening new sites to power generation.

Most offshore wind turbines today are fixed to the seabed, so-called bottom-fixed, and in more shallow waters. The next generation of turbines are designed to float in the water allowing development further out to sea where winds are stronger, but the water depths make bottom-fixed designs uneconomic.

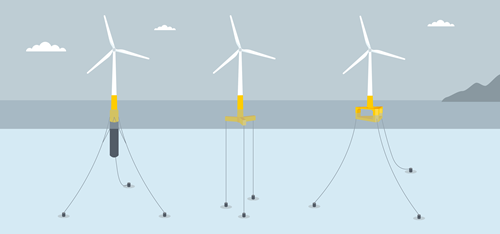

Most offshore wind floater designs are similar to the ones applied for the oil and gas platforms. Floating turbines are moored to the seabed with multiple mooring lines and anchors, in much the same way as a floating oil platform. Floating wind turbine motion controllers use sensors to regulate the turbine blades in adverse conditions, reducing strain on the moorings and maximising electricity production.

There are three main designs of floaters for offshore wind - spar buoy, tension leg platform and semi-submersible and both steel and concrete can be used as a construction material.

Océole will select the best suited floating wind technology for their projects.

What are the advantages of floating offshore wind?

Floating wind has a higher capacity factor thanks to stronger and more consistent wind further out to sea

Removing water depth constraints allows us to select the best sitess

Floating wind represents a huge potential along the French coasts (source : FEE)

Learn more about floating

VIDEO: How Hywind floats – short explainer video with demonstration (00:45)

WEB: How Hywind works – technical description and dimensions

WEB: The story of how Hywind was born - the best ideas often happen when you least expect them…

WEB: Floating offshore wind – overview of Equinor’s activities

VIDEO: The future is afloat - Equinor content in partnership with FT (03:27)